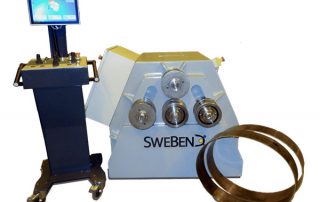

SB4 Series Section Bending Machines

The SweBend SB4 Four Roll Section Bending Machine Series starts with the SB4B-55 and ranges up to the SB4-240S. The machines are extremely sturdy in design and have more power compared to any other section bending machine on the market.

- Number of rolls – 4-rolls

- Operation – hydraulic

- Sheet thickness: Min: 2mm / Max: 200mm

- Sheet size: Min: 1000mm / Max: 12000mm

- Type ‘B’ is the basic model without guide rolls

- Type ‘S” is with fully hydraulic guide rolls, allowing users to bend and compensate/correct all types of sections

- Both types have the same geometry and capacities

Standard Equipment

- Polished roll surface

- Automatic prebending and rolling

- Tiltable bending rolls

- Rotational speed variation

- Oil cooling system

- Double-pinch pyramid design, enabling pre-bend at both ends of the plate

- Hardened & Ground roll

- Electronic control of roll parallelism

- Four digital readouts (= both roll ends)

- Wireless control unit with joysticks

- 3 hydraulic powered rolls by their own respective hydraulic motor

- SKF bearings only

- Top electrical & hydraulic components from the best suppliers.

- Emergency stop button

- CE-Certification

Optional Features

- SEVEN – SweBend’s own trademarked Graphical CNC SYSTEM

- Cone bending device (key or roll)

- Material ejection devices

- Special rolls with contour, grooves etc, to allow bending plates with flanges and/or ribs

- ”Turbo Production” kits

- Integration in production cells, including communication with other software systems

- Changeable top roll for small diameters

- Special color and design

- Calibration Systems

- Side supports

- Top support with electric or hydraulic operation

SweBend design and produce the strongest and most user-friendly machines on the market with the highest drive torque and strongest bending power compared to any other plate roll of the same size.

- Heavily proportioned machine frames and mechanical parts

- Top components from the best suppliers.

- High quality, hardened rolls

- SKF components, the world famous Swedish Bearing Company.

Image Gallery

Downloads

“Our business succeeds on the Worldwide market by delivering quality parts, on time and at a competitive cost. Often, our major structural contracts are won on capability to deliver against challenging designs in a world of ever more complicated geometries. Working with WJS Machine Tools and their partners has allowed us to develop machines for this purpose”